How to Make Your Own Homebrewed Hard Seltzer + Hard Seltzer Recipes

Let’s face it. As beer lovers, seltzer is a controversial topic at best. Beer snobs like me often turn our noses up at people drinking fizzy, lightly flavored alcoholic water. But there’s something else we have to face: the stuff just really isn’t that bad. Sure, you don’t enjoy a seltzer in the way you can enjoy a great beer, but it’s hard to ignore that it is refreshing, light, and still has a little kick.

As a homebrewer, my biggest issue with hard seltzer is the price. Somehow, that fizzy water with almost no ingredients in it costs as much as a decent craft beer.

Once it became impossible to ignore the popularity of hard seltzer, I decided to figure out how to make it myself. I keep an extra keezer in my home brewery for experimental beers or non-beer options for guests, so I had a few extra taps to play with to try out this popular trend anyway.

Here’s the good news: it turns out that hard seltzer drinks are very easy to make, and EXTREMELY cheap. Like, close to free when you use the fermented option. The batch that I used as the example for this article cost well under $10 to make for a 5-gallon batch. There are a couple of ways to make it, which I’ll describe below.

What is Hard Seltzer?

Hard seltzer is an alcoholic beverage made from carbonated water, alcohol, flavoring, and sometimes a bit of extra sugar or other sweetener to make it more palatable. These light, fizzy alcoholic beverages usually clock in at about 5% ABV and are relatively low-calorie when compared to beer or sugary cocktails. The refreshing, hydrating feel of drinking hard seltzers when combined with the (at least perceived) health and weight loss benefits when compared to beer have made seltzer a popular drink that will likely remain widely consumed for a long time.

Hard seltzer goes by many names, including seltzer, spiked seltzer, alcoholic seltzer, alcoholic sparkling water, mature seltzer, adult seltzer, hard sparkling alcohol water, hard soda water, seltzer water, hard club soda, and others. All of these names refer to the same thing – fizzy, carbonated water with alcohol in it.

How is Hard Seltzer Made?

Most often, hard seltzer is made by fermenting cane sugar, sometimes called a sugar wash, with water, yeast, and yeast nutrients. In some areas, where required by law, seltzer may be made with a very neutral malt and then stripped of color and flavor.

There are also a few seltzers out there now that are a simple cocktail made by mixing a neutral grain alcohol like vodka with carbonated water and flavor. There is some question as to whether those are truly hard seltzer or a canned cocktail, but the end result is a boozy, carbonated water with a light flavor either way.

If you’re interested in making your own hard seltzer, we offer homebrew (or at least homemade) recipes later in this article for how to make hard seltzer at home by either mixing it from premade alcohol or by naturally fermenting it yourself.

History of Seltzer

While hard seltzer and similar products like Zima, an early malt “cooler”, have been around for a while now, but started to gain popularity rapidly in the United States in 2018. By 2019, White Claw had dominated the market for hard seltzer, but other options rapidly came to market, including Truly, High Noon, and Bon VIV.

Most macro beer brands got on board and started producing seltzers as well, including Bud Light Seltzer, Natural Light Seltzer, Corona Hard Seltzer, Michelob Ultra Seltzer, and Coors Seltzer.

Now, you can even find a hard seltzer on tap at many small, independent microbreweries. It’s hard to blame them, though. With seltzer’s continued popularity and the relatively low cost to produce it when compared to beer, it certainly makes good business sense to offer hard seltzer on any taplist.

Seltzer vs Beer vs Wine vs Cocktails

Like most alcoholic beverages, it can be difficult to draw a clear line between what a specific drink actually counts as. If you make seltzer by mixing vodka, water, and flavoring, then carbonate it, is it seltzer? Is it a cocktail? If seltzer is made by fermenting malt, could it be considered beer? A malt beverage?

Seltzer, beer, and wine are all made by using yeast to ferment sugar into alcohol. One of the main differences between the three is the source of the sugar that is fermented.

Beer is made by fermenting sugars extracted from malted grain, usually barley specifically.

Wine is made from fermenting the sugar of grapes or other fruits.

Seltzer is generally fermented from cane sugar, although there are some cases in which malted grain or fruit sugar may be used. In those cases, the flavor and color of the fermented beverage is stripped out so that it is generally clear and fairly neutral in flavor. The seltzer is then flavored with either artificial or natural flavoring.

What are the Primary Ingredients in Hard Seltzer?

Hard seltzer is made from five main natural ingredients: water, fermentable sugar, yeast, yeast nutrient, and flavoring. You can even buy most of the hard seltzer ingredients from a grocery store!

Water

Water is an underappreciated ingredient in beer-brewing, and the quality, mineral content, and hardness of water makes a huge difference in the final product.

In seltzer, which is essentially just flavored alcoholic water, the water that it is made from is even more important. Seltzer is best made from neutral water, meaning that it does not contain a high mineral content and isn’t hard.

Most bottled water or tap water contains added minerals, which can impart sharp flavors that make the seltzer unpleasant and a bit like rubbing alcohol.

The best water for making hard seltzer is either distilled water or reverse osmosis water (RO water).

Distilled water is water that is boiled, turned into steam, and then cooled to recondense it into water. Distilling water removes all of the impurities in it and also strips the water of minerals, making it the most pure and neutral water possible. This neutrality makes it a great option for making hard seltzer.

Reverse Osmosis (RO) water is purified by forcing the water through a semipermeable membrane under pressure, which separates ions, particles, and molecules other than water molecules from the water. Like distillation, the RO process results in a very neutral water profile that is excellent for making hard seltzer.

Sugar/Fermentables

While seltzer can be occasionally made with malted grain for legal reasons, it is generally fermented from either cane sugar or corn sugar. Either works well as long as you use the right yeast and yeast nutrients to ensure that you have a healthy environment for fermentation.

Yeast

When brewing beer, different yeast strains are used to impart different flavors, aromas, and mouthfeels. With seltzer, the goal is generally to produce as little color, flavor, and aroma as possible. As such, the best yeasts for making seltzer are usually neutral and ferment very clean and dry. Any neutral ale yeast strain will work, as will most champagne yeasts. We have had better luck with EC-1118 than we have had with beer yeast, but other people have reported great success with it.

For some flavors of seltzer, you may find that different yeasts impart different flavors that compliment the flavor chosen, but when you’re first starting out, we recommend a clean, neutral yeast.

A few of the yeasts we recommend for making hard seltzer are:

Nutrients/Additives

When brewing beer, the malt contains minerals, vitamins, and amino acids that the yeast needs to efficiently convert the wort into beer.

Plain corn sugar or cane sugar in water is not a very healthy environment for most yeast, and does not provide these necessary nutrients to the yeast, so you need to use additives to ensure that the yeast is healthy enough to turn all of that sugar into alcohol. Low yeast health can cause poor flocculation and a yellowish color and haze in your finished seltzer.

The right blend of vitamins, minerals, and nitrogen can help you achieve a neutral, dry, clean, and clear hard seltzer. To make things easier, you can just use a pre–mixed set of nutrients specifically designed for seltzer, like Propper Seltzer. If you prefer to use your own blend of yeast nutrients to make your seltzer, here are a few popular options used for seltzer:

- Fermaid O Yeast Nutrient

- Potassium bicarbonate

- Sodium bicarbonate

- DAP (diammonium phosphate)

- FermFed DAP Free

- Go Ferm Protect

Flavors

Before We get into the process of how to brew hard seltzer, we need to talk about flavoring briefly. Seltzer is usually fruit flavored. You have a couple of options depending on the method you’re using to make your seltzer. For the mixed recipe below, you can even just use a flavored vodka.

The two primary options you have for flavoring your seltzer are to use natural flavor extracts or to create an infusion by cold steeping fruit, spices, or whatever else you want to flavor your seltzer with in a neutral grain alcohol like Everclear or vodka. All you need to do is use a couple of cups of spirit and soak the fruit in the refrigerator for a day or two until the flavors are imparted.

You can even use real fruit or fruit juice by adding it during a secondary fermentation, but it requires a lot of fruit to achieve a strong flavor.

Generally, the easiest way to flavor your hard seltzer is to add flavoring (artificial or natural) concentrate after fermentation to give the seltzer its fruit flavor. Most seltzer kits include flavoring, and you can also buy it separately. Here are a few good options for fruit flavors for seltzer. These natural flavorings from MoreBeer work well and don’t add too much cost to your seltzer:

- Cherry Fruit Flavoring

- Peach Fruit Flavoring

- Raspberry Fruit Flavoring

- Strawberry Fruit Flavoring

- Blackberry Fruit Flavoring

- Blueberry Fruit Flavoring

- Apricot Fruit Flavoring

- Cranberry Fruit Flavoring

Equipment Needed to Make Hard Seltzer

Hard seltzer requires very little equipment, and if you homebrew your own beer or make your own wine, you should already have everything you need. The pieces of homebrewing equipment required to make hard seltzer are:

- Brew Kettle

- 5.5-6 Gallon Fermenter (either a glass carboy, a bucket fermenter, or a conical fermenter will work. Click here to learn about The Pros and Cons of Glass vs Plastic vs Stainless Steel Homebrewing Fermenters. Click here to see our Guide to the Best Conical Fermenters for Homebrewing)

- Airlock

- Hydrometer (Click here to learn how to use one!)

- Cleaner / Sanitizer for all equipment. We recommend PBW and Star San.

How to Make Hard Seltzer: Mixed Cocktail Seltzer Recipe

I don’t really consider this method to be brewing (more “assembling”), but it’s worth mentioning because it is cheap, easy, and makes a solid final product if you have a kegging system.

One way to quickly and easily have hard seltzer on tap at home is to mix water (I highly recommend using distilled or reverse osmosis water to avoid off flavors), flavoring, and a neutral spirit like grain alcohol (or vodka) in a keg to your desired strength (generally about 5%). You can even lightly sweeten it, although I actually think it’s better unsweetened.

Once it’s your desired flavor and strength, you can just force carbonate it in your keg. It’s not really “brewing”, but it works, and honestly makes a pretty decent “homemade” hard seltzer in a matter of minutes.

To figure out how much liquor you need to achieve the desired alcohol content, you can use this formula:

- Liquor Volume = (Desired ABV x Desired Total Volume) / Liquor ABV

- For a 5-gallon batch at 5% using 80 proof (40% ABV) vodka, you would calculate the following:

- Liquor Volume = (.05 x 5) / .4

- Liquor Volume = 0.625 Gallons (2.365882 Liters)

From here, I’d round up just a bit and use a total of 2.5L of vodka to make it easy to purchase. Just buy a standard 1.75ML bottle and a standard 750mL bottle of 80 proof vodka and you’ll end up with 5 gallons of just about 5% ABV seltzer. It’s not EXACT, but it’s close enough for making it at home!

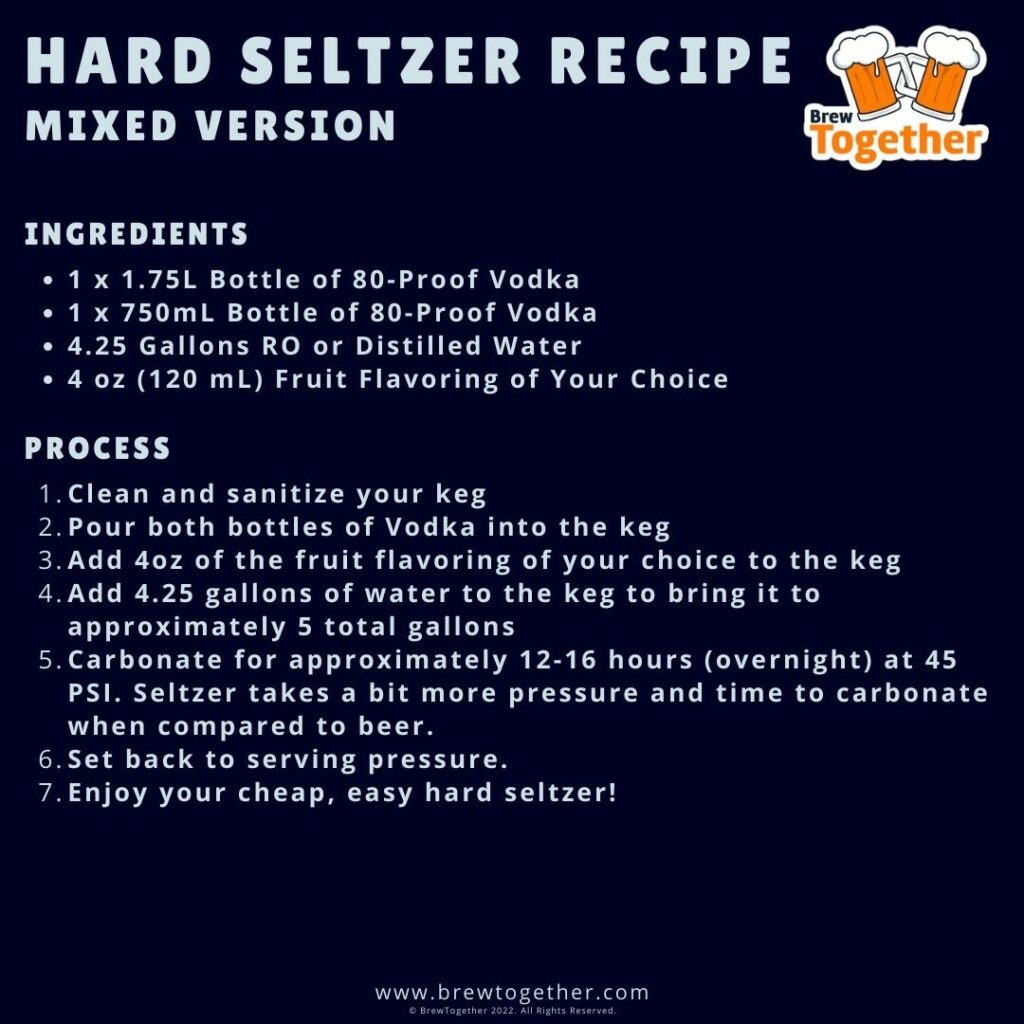

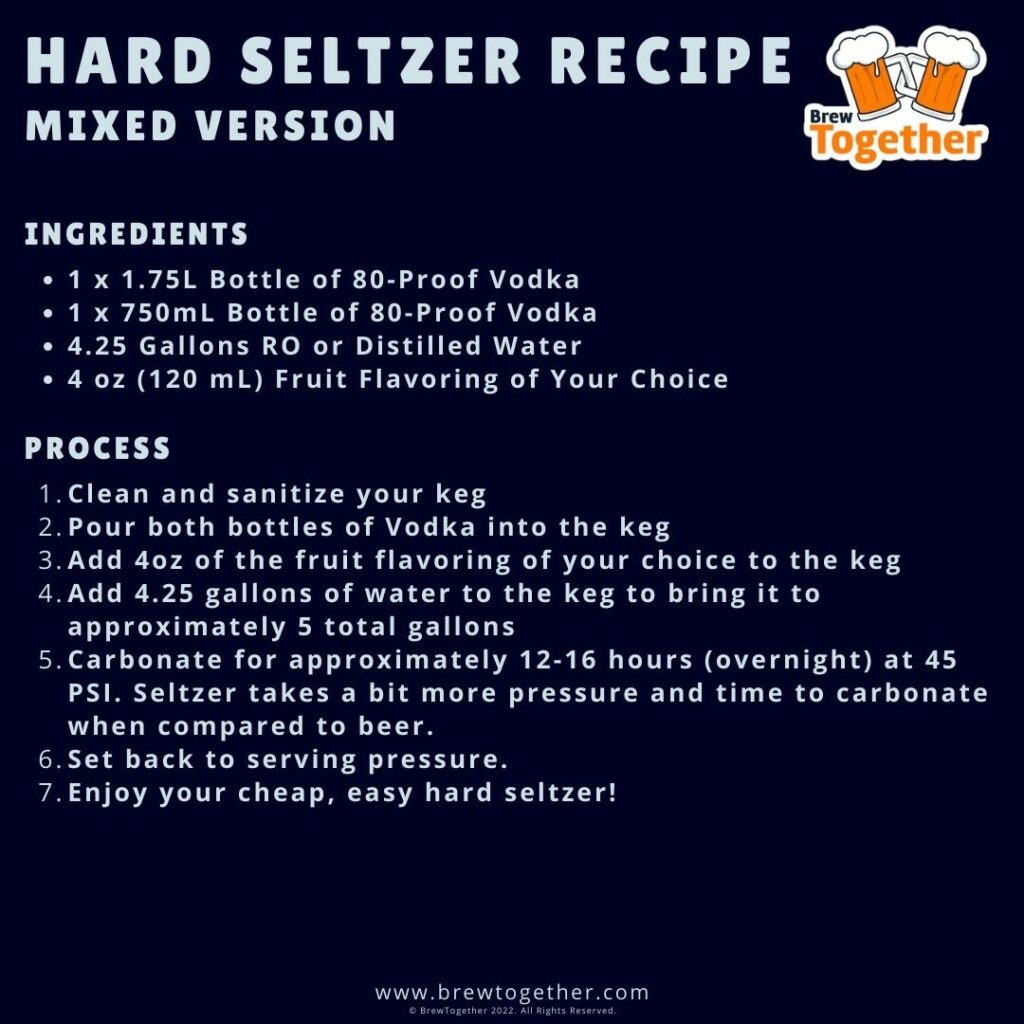

Here’s an easy recipe for mixing up a batch of your own hard seltzer in a keg:

- 1 x 1.75L Bottle of 80-Proof Vodka

- 1 x 750mL Bottle of 80-Proof Vodka

- 4.25 Gallons Purified Water

- 4 oz/120 mL Fruit Flavoring of Your Choice (Use instructions for the brand of flavoring you purchase. The ones we use from MoreBeer mix at a ratio of 4oz per 5-gallon batch)

Here’s how to make it! It’s very easy:

- Clean and sanitize your keg. If you aren’t sure how to do that, check out our guide to how to clean a corny keg or look at our guide to how to build your own automatic keg washer.

- Pour both bottles of Vodka into the keg

- Add 4oz of the fruit flavoring of your choice to the keg

- Add 4.25 gallons of water to the keg to bring it to approximately 5 total gallons

- Carbonate for approximately 12-16 hours (overnight) at 45 PSI. Seltzer takes a bit more pressure and time to carbonate when compared to beer.

- Set back to serving pressure.

- Enjoy your cheap, easy hard seltzer!

How to Make Homebrewed Hard Seltzer (Fermented Seltzer Recipe)

While the mixed recipe above makes a decent, refreshing beverage, it doesn’t quite feel like homebrewing. Here’s a recipe for how to make your own truly homemade hard seltzer by fermenting sugar! The sugar brew version is still very easy to make, and costs almost nothing if you already have the equipment!

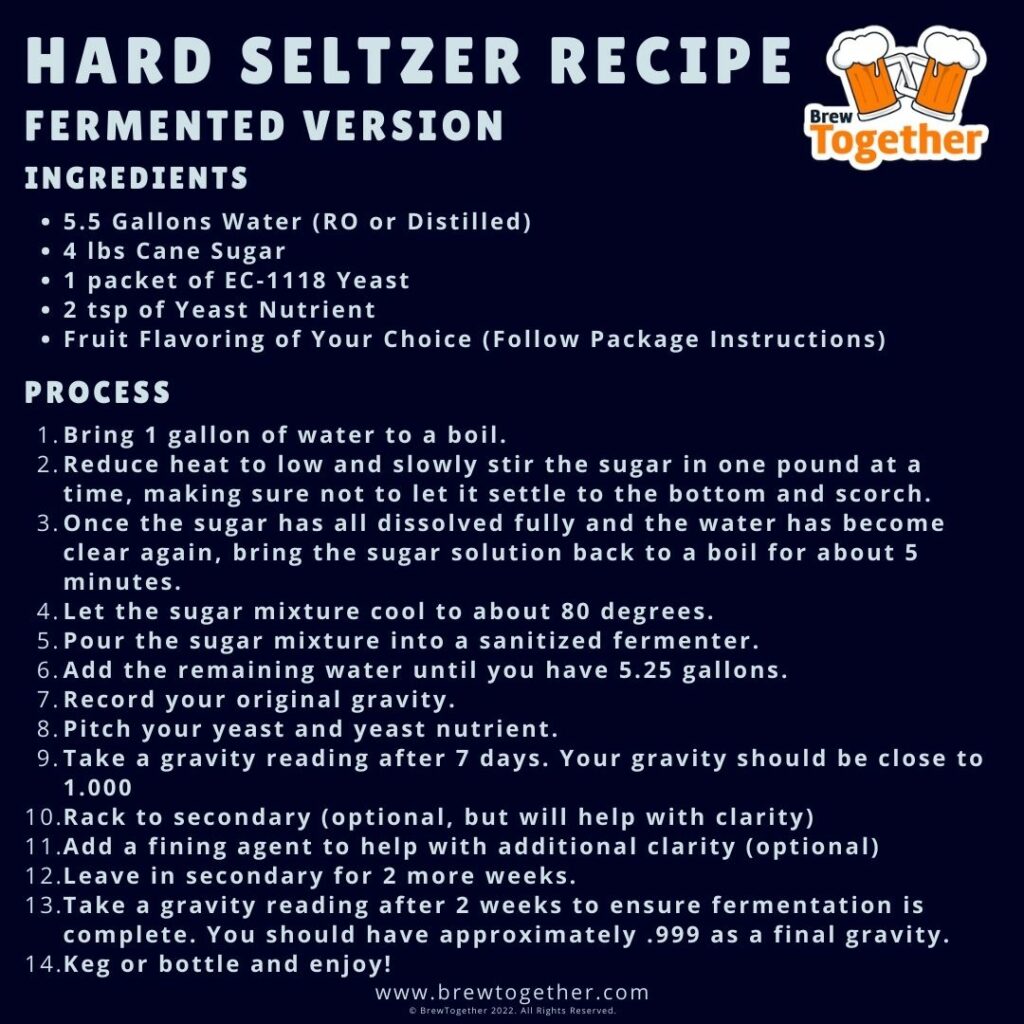

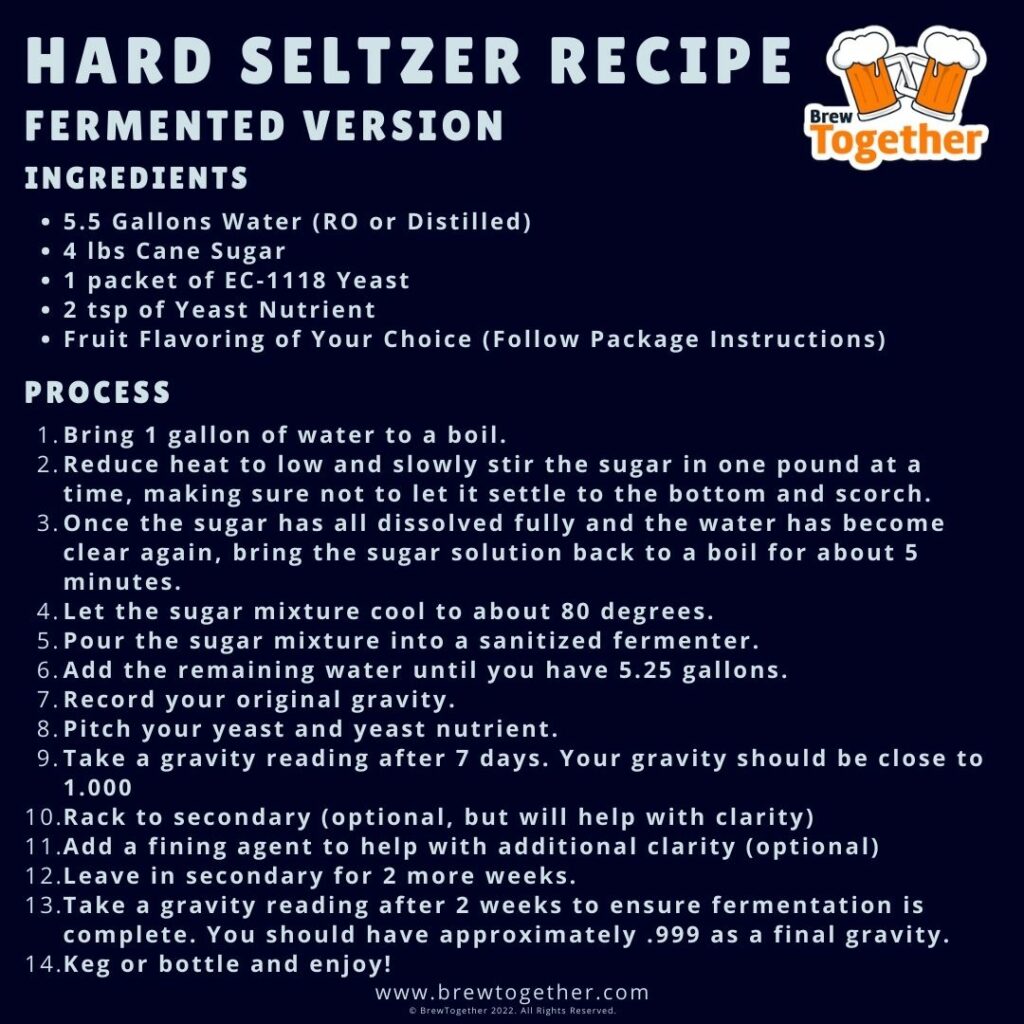

Ingredients

- 5.5 Gallons of Water

- I highly recommend using either distilled or reverse osmosis water to avoid off flavors. I just bought cheap purified drinking water by the gallon that was purified with reverse osmosis.

- 4 – 5 lbs of Sugar (depending on your desired ABV. More information is below on how much sugar you need for your desired ABV.)

- Like we explained earlier in the article, you can use either corn sugar or white table sugar. For this recipe, we recommend using plain old white cane sugar.

- 1 packet of EC-1118 Yeast

- Yeast Nutrient

- Yeast has trouble getting started in plain sugar water, so the yeast nutrient is very important for this recipe.

- The flavoring of your choice

Brew Day

Here are the major steps you need to complete on brew day to homebrew hard seltzer:

Determine Your Desired ABV

First, you’ll need to determine the desired ABV of your finished seltzer. Most commercial seltzers are about 5% alcohol, so we recommend shooting for about 4% – 6% if you’re looking for something similar to what you’d buy in a store.

The formula for ABV is (OG – FG) x 131. Pure cane sugar yields 42 gravity points per pound per gallon and is 100 percent fermentable, so one pound of sugar in a 1-gallon batch would be (0.046 – 0.000) x 131 = 6.026% ABV per gallon. For a 5-gallon batch, that would be 1.2% ABV.

Here’s a little cheat sheet to figure out how much sugar you need to add to achieve your desired ABV.

- 1lb of white sugar in a 5-gallon batch of hard seltzer = 1.2% ABV

- 2lb of white sugar in a 5-gallon batch of hard seltzer = 2.4% ABV

- 3lb of white sugar in a 5-gallon batch of hard seltzer = 3.6% ABV

- 4lb of white sugar in a 5-gallon batch of hard seltzer = 4.8% ABV

- 5lb of white sugar in a 5-gallon batch of hard seltzer = 6% ABV

- 6lb of white sugar in a 5-gallon batch of hard seltzer = 7.2% ABV

- 7lb of white sugar in a 5-gallon batch of hard seltzer = 8.4% ABV

The Boil

Bring 1-2 gallons of water to a boil. If you’re using more than 4 lbs of sugar, use 2 gallons. For less than 5 pounds of sugar, you can just boil one.

Reduce heat to low.

Slowly stir the sugar in one pound at a time, making sure not to let it settle to the bottom and scorch.

Once the sugar has all dissolved fully and the water has become clear again, bring the sugar solution back to a boil for about 5 minutes.

Let the sugar mixture cool to about 80 degrees. If you have one, you can use a wort chiller (here’s a list of our favorite ones if you’re in the market for one) to cool it faster. Because the volume is so low, you can also just put the whole kettle in an ice bath to cool it faster if you don’t have an immersion chiller.

Fermentation

Once cooled, pour the sugar mixture into a sanitized primary fermenter.

Add the distilled or RO water until you have just over 5 gallons (about 5.25).

Record your original gravity using a hydrometer. If you’re not sure how to use one, check out our guide to how to take gravity readings using a hydrometer.

Pitch your yeast and yeast nutrient.

After 7 days of fermentation at room temperature, take a gravity reading. Your gravity should be close to 1.000

If desired or if you are adding fresh or frozen fruit for flavor, you can rack the seltzer to a secondary fermenter. This step is optional, but will help with clarity. After racking to secondary, you can add a fining agent to help achieve more clarity as well.

Most of the kits seem to recommend Chitosan, which is derived from shellfish. Obviously, you shouldn’t use that if you have an allergy or dietary restriction.

Other options for fining agents are:

- Irish moss

- Whirlfloc tablets

- Gelatin (animal-derived)

- Isinglass (animal-derived)

Leave in secondary for at least 1 week, but ideally 2.

Take a gravity reading after 2 weeks to ensure fermentation is complete. You should have approximately .999 as a final gravity.

Bottling/Kegging

Once your seltzer is completely fermented, you will need to carbonate it so that it is fizzy like a commercial seltzer. You have two main options for how to achieve carbonation in a homebrewed hard seltzer. Keep reading to learn about how to carbonate hard seltzer in a bottle, or how to carbonate it in a keg.

If you’re not sure which process you’d prefer to use, check out our guide to the pros and cons of bottling vs kegging homebrew to learn more. If you’re interested in kegs but not sure where to start, check out our Ultimate Guide to Beer Kegs.

How to Bottle Hard Seltzer

Before we go over how to bottle hard seltzer, I’ll admit that I highly recommend kegging your seltzer if you have the option. Bottle conditioning doesn’t seem to carbonate seltzer as well as it does for beer, and some people have expressed safety concerns with glass bottles for seltzer because the carbonation can be a bit inconsistent, which can result in bottle bombs.

Because we don’t backsweeten seltzer at all, as long as you have reached a low final gravity, you should be safe to bottle condition. Just remember to never try to sweeten it before bottling or you’ll get bottle bombs, which is unsafe and makes a huge mess. Just be aware that bottle conditioning will impart some yeast flavors that are undesirable in seltzer, and it will affect the clarity.

To bottle seltzer, follow these steps:

- Sanitize 2 cases (48) of pry-off bottles and all of your bottling equipment.

- Using your autosiphon, rack the seltzer from your carboy to a sanitized bottling bucket.

- Do your best not to stir up the sediment at the bottom of the carboy so that you don’t rack it into your bottles.

- Add your desired flavoring agent (a little goes a long way!) into the bottling bucket and gently stir with a sanitized spoon.

- Bring 1-2 cups of water to a boil and slowly add 5oz of priming sugar.

- Add the sugar mixture to the bottling bucket and gently stir to make sure it’s mixed well.

- Fill each bottle. If using a bottling wand (which we recommend!), fill each bottle completely and then remove the wand, which will leave the proper gas gap. If you’re not using a bottling wand, leave a couple of inches of space in the neck of each bottle.

- Cap each bottle using a capper and pry-off caps.

- Let the bottles condition for 2-3 weeks before drinking.

- Enjoy!!!

How to Keg Hard Seltzer

Kegging is by far the better option for carbonating and serving hard seltzer (and often, beer too! Click here to check out the pros and cons of kegging vs bottling homebrew!). It doesn’t cause any of the off flavors caused by yeast during natural fermentation, and will give you a final product much closer to that of a commercial seltzer.

To keg your seltzer, follow these steps:

- The night before kegging, cold crash your seltzer in the carboy.

- Ensure that your keg has been thoroughly cleaned and sanitized.

- Place the carboy on a steady surface above the keg.

- Siphon the seltzer into the keg using a sanitized siphon. We recommend this autosiphon, which makes life a lot easier!

- Make sure the siphon hose is long enough to reach the bottom of your keg to avoid adding too much oxygen to the seltzer.

- Add the desired flavoring extract.

- Seal the keg and attach the gas line, making sure to check for leaks (they’re definitely not fun when they happen!)

- Set your Co2 Regulator to 30-50psi. Water needs a LOT more pressure than beer to carbonate!

- Roll the keg on its side or gently shake it for 15-20 minutes to absorb as much Co2 as possible.

- Take a sample every few minutes to make sure you don’t overcarbonate it.

- It’s ready to drink immediately – enjoy!!!

Best Hard Seltzer Recipe Kits

While it’s easy to make your own seltzer from store bought ingredients, if it’s your first time making hard seltzer, you might be more comfortable with making it from a kit. These kits contain everything you need to make your own hard seltzer, and come in a variety of favorite flavors. Here are some good choices for hard seltzer kits that you can choose based on your flavor preference:

- Wild Water Hard Seltzer Recipe Kit – Classic (Unflavored)

- Wild Water Hard Seltzer Recipe Kit – Cherry

- Wild Water Hard Seltzer Recipe Kit – Peach

- Wild Water Hard Seltzer Recipe Kit – Raspberry

- Wild Water Hard Seltzer Recipe Kit – Strawberry

- Wild Water Hard Seltzer Recipe Kit – Blackberry

- Wild Water Hard Seltzer Recipe Kit – Blueberry

- Wild Water Hard Seltzer Recipe Kit – Apricot

- Wild Water Hard Seltzer Recipe Kit – Cranberry

Is Hard Seltzer Gluten Free?

Because most hard seltzer is fermented from either corn sugar or cane sugar, it is naturally gluten-free. The most commonly used sugar for commercial seltzer is cane sugar, which is gluten-free.Because hard seltzer is gluten free, it makes it a great option for those with gluten intolerance or gluten allergies. While seltzer is almost always gluten free, make sure you check the specific brand of seltzer you’re planning on consuming if you have a severe gluten allergy or celiac disease.

Is Homebrewed Hard Seltzer Gluten Free?

Homebrewed hard seltzer following the instructions above is completely gluten free! Make sure you always check all of the ingredients you are using for gluten if you have a severe allergy.

Is Truly Hard Seltzer Gluten Free?

According to their website, “Truly Hard Seltzer is crafted with simple, naturally gluten-free ingredients and contains alcohol made from cane sugar.”

Is Natural Light (Natty Light) Hard Seltzer Gluten Free?

Natural Light / Natty Light Seltzers appear to be 100% gluten free from what we could find from retailers. Be cautious, though, because Naturdays beverages, which are similar to seltzers, are not gluten free!

Is Bud Light Seltzer Gluten Free?

According to their website, Bud Light Seltzer is “gluten-free and naturally flavored”. This only applies to products sold in the United States. The version of Bud Light Seltzer sold in Canada is made with malted grain and is not gluten free!

Is Michelob Ultra (Mich Ultra) Seltzer Gluten Free?

According to their website, all Michelob Ultra Seltzers are 100% gluten-free.

Is Coors Seltzer Gluten Free?

According to their website, Coors Hard Seltzer products are certified gluten-free by GFCO.

Is Press Seltzer Gluten Free?

According to their website, Press Alcohol Seltzer is gluten removed. Gluten removed products may not be safe for those with severe gluten sensitivity, so use caution.

Thank you!

Have you had any experience in homebrewing hard seltzer? Leave a comment below or post in the forums to join the conversation!

If you found this article to be helpful, please share it with your friends using the social media share buttons below! We need your help getting the word out about BrewTogether!

Still have questions about brewing your own beer? Leave a comment below or post in the forums! The BrewTogether Community is made up of an awesome group of homebrewers around the world that are always supportive and happy to help answer your questions about brewing your perfect beer!

If you’re not a member of BrewTogether, we’d love for you to join! BrewTogether is completely free, and signing up is easy! Click here to join! We’d love to have you as a member of the BrewTogether Community!

Now using BrewTogether is easier than ever! Download the FREE BrewTogether Mobile App – available on both the Apple App Store and the Google Play Store! The BrewTogether App is completely free and drastically improves the experience of using BrewTogether on a mobile device.

Affiliate Disclosure: BrewTogether is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites. BrewTogether is also a participant in an affiliate program with MoreBeer, our favorite online homebrewing equipment/ingredients retailer. Some of the links in this article are affiliate links, which means that if you choose to make a purchase after clicking the link, I will earn a small commission at no additional cost to you. Please feel free to reach out with questions. Thank you for your support!

I followed the recipe above in every detail the only variable was I bought lavlin 71b yeast . I’m brewing a 5 gal batch with 7 lbs of cane sugar with 2 tsp of yeast nutrients on brew day. It’s been about 2 wks and it’s only dropped 5 pts from 1.065 to 1.060. I put another tsp of yeast nutrients in today thinking it might be stuck in fermination. Looking for any help out there to help finish this brew.

Hi Trey! Sorry for the delayed response! Sorry to hear your fermentation got stuck. If it doesn’t have an off smell, pitching another pack of yeast should hopefully get you across the finish line.

I’m guessing you pitch the yeast and nutrient between step 8 and 9. Sorry newbie here.

Hi @blaith_belangee! Great question – I can’t believe we didn’t state when to pitch the yeast and nutrient!!! We added that step right after you take the OG – thanks so much for bringing it to our attention!